Nathan, Ebrahim

Design office

Michel, Sébastien

Construction department

From study to design, from commissioning to maintenance, the SFEC company, located on the outskirts of Lyon, has been involved, since its creation in 1983, at all levels to create efficient water treatment systems, robust and reliable in France and internationally.

Water, the common heritage of humanity, is a rare resource and the challenge of the third millennium. Treating it to meet a particular application or making it suitable for human consumption are at the heart of the know-how of the SFEC company.

Our qualified and experienced engineers offer solutions that cover a large number of cutting-edge processes and technologies meeting a wide range of applications such as:

– water purification (municipalities, public authorities, living areas, agri-food industries, bottling plants, etc.),

– the production of ultrapure water (hospital establishments, pharmaceutical industries, electricity or semiconductor production industries, etc.),

– the reprocessing of process water (industrial or tertiary sector) for its recycling or reuse in various forms.

We master a wide range of treatment and disinfection processes including, among others, softening, sand filtration, ultrafiltration, microfiltration, nanofiltration, reverse osmosis, electrodeionization, ultraviolet, ozonation …

The “raw” water that we treat or reprocess through our facilities comes from different sources: underground (wells, boreholes, catchments, groundwater tables, etc.), surface (seas, rivers, streams, lakes, rivers, reservoirs, etc.) artificial etc.), distribution networks or specific process. This water can be polluted by micro-organisms, chemical substances, toxic residues, etc. The complexity of the treatment is all the higher as the quality of this water is poor.

SFEC treatment systems meet the criteria of quality, hygiene, safety and guarantee water that complies with the most demanding standards: Public Health Code, European Pharmacopoeia, WHO, ARS, etc.

All components and equipment used in the construction of our facilities are from recognized European brands.

The choice of our suppliers is based on a responsible and environmentally friendly societal approach. It takes into account three CSR criteria in particular: social, environmental and economic.

OUR JOBS

Our in-house design and engineering office can solve the most complex cases of treatment in the field drinking water(municipalities, public authorities, living centers, bottling companies, etc.), the medical sector (sterilization, dialysis, pharmaceutical laboratories, etc.) or industrial (drinks, food processing, etc.).

Each project is subject to a personalized approach that includes both the physico-chemical analysis of the raw water to be treated, and the assessment of customer needs up to the design and sizing of complete drinking water treatment or water treatment systems.

Our solutions integrate advanced technologies taking into account the best technical-economic compromise as well as the constraints regulatory and environmental.

The objective of our engineers, in the study and general design of each installation, is to provide answers :

…to provide our customers with autonomous, safe, robust, ergonomic and durable SFEC water treatment systems.

Our technicians can also assist you in technical assistance missions or diagnosis of treatment processes. These missions assistance allow our customers to benefit from preventive and corrective recommendations in the design of their treatment systems of current or future water, including the development of specific and adapted innovative solutions. As such, we guarantee you :

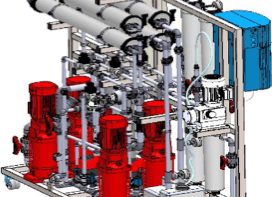

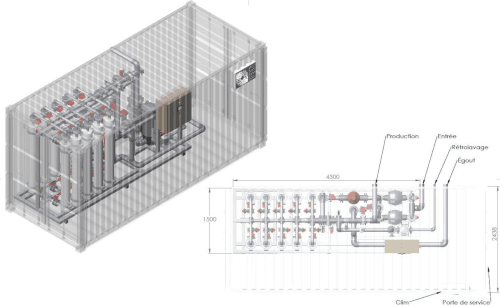

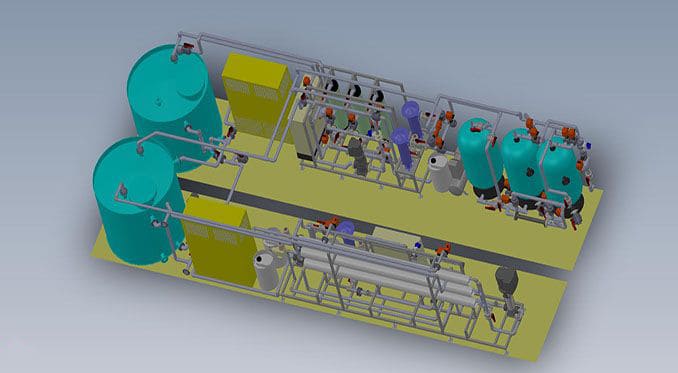

Our workshop ensures the custom construction of any type of water treatment unit on chassis (skid) or containerized.

Do not hesitate to ask us to assist or accompany you in your projects.

Maintenance is the continuity of our job as designer and constructor. It is also a witness to our total involvement in the life of the equipment for domestic and professional customers.

The proximity, flexibility, responsiveness and availability make our company a key player in the field of system maintenance water treatment.

Our offer is available in many facets ranging from simple punctual repair on request to the multi-year preventive and / or corrective maintenance contract, shared, … in different business sectors (food, community, hospital, pharmaceutical …).

All our services are carried out in the state of the art, with suitable tools, in compliance with the rules of health and safety.

Proposed services:

Different types of Maintenance Contracts :

Do not hesitate to contact us to support you in the maintenance of your water treatment facilities !

Our purchasing and trading department holds a stock of equipment and consumables for immediate availability. It can also supply you with spare parts of all brands, at the best prices, to ensure the smooth running of your processing plants. Worldwide delivery.

The brands we sell are exclusively recognized international names in water treatment.

OUR FIELDS OF APPLICATION

To meet your various water needs (potabilization, filtration, purification, desalination, reuse, etc.) we put all our skills and know-how at your disposal to provide you with the best solutions.

There are different categories of water intended for human consumption: natural mineral water, spring water and public supply water.

There are different categories of water for human consumption : natural mineral waters, spring waters and public water supplies.

There is today a growing degradation of the quality of raw water by the increase of their pollution (nitrates, pesticides, drug residues, micropollutants of all kinds…) with repercussions on public health.

This is why communities or agro-food industries must today resort to increasingly sophisticated means of treatment and disinfection to obtain water suitable for human consumption.

SFEC is able to offer you complex treatment (multi-barrier) and disinfection systems, implementing several levels of filtration, in order to finally obtain a water of quality answering to the French and European regulations and standards. International agreements on drinking water (Directive européenne 98/83 of 3 novembre 1998, OMS (Organisation Mondiale de la Santé…).

Our strong points :

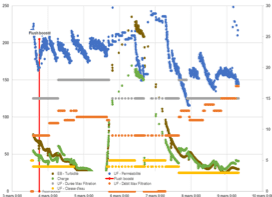

SFEC treatment facilities are ideal for removing cloudy substances, particulates and undesirable microbiological organisms such as bacteria, viruses and parasites in raw water. Even when turbidity or microbiological contamination peaks are observed after precipitation, the facilities provide a uniform quality filtrate without turbidity or pathogens.

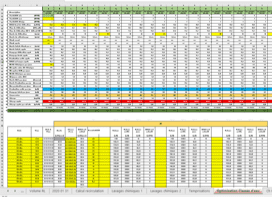

A programmable controller provides fully automatic operation of the entire treatment facility. The different parameters are entered using a touch screen. The variety of control variants ensures maximum flexibility and operational safety. Depending on the quality of the raw water used, cleaning as needed can be supported by an optimized addition of chemicals. All important operating parameters are recorded electronically.

SFEC treatment units combine several filtration and / or disinfection methods that are used together or sequentially. Each method having its favorite target.

The drinking water thus produced responds to a treatment process totally controlled by the SFEC, which relies in particular on the following technologies :

Industry covers a range of water uses that vary widely in terms of both quantity and quality.

The industry covers a range of extremely variable water uses, both in quantity and quality.

Industrialists use water :

Remarkable solvent, water is also widely used by the chemical industry to wash, dissolve, extract, synthesize a large number of molecules.

In addition, the growing demands for the protection of resources and the environment combine to impose on industrialists an ever more rigorous management of their water.

To meet all these needs, SFEC offers physical and / or chemical treatments to produce water that does not damage your facilities during its passage and brings you innovative technical responses.

Our strong points :

The SFEC treatment units for industrial use are dimensioned on a case by case basis and make it possible to provide concrete and economical solutions to industrialists wishing to produce water that meets the specificities of their process…

Mounted on freestanding skids or in containers, these units can be adapted to the most dangerous environments (ATEX, …) and the most severe constraints.

A programmable controller provides fully automatic operation of the entire treatment facility. The different parameters are entered using a touch screen. The variety of control variants ensures maximum flexibility and operational safety. Depending on the quality of the raw water used, cleaning as needed can be supported by an optimized addition of chemicals.

SFEC treatment units combine several filtration and / or disinfection methods that are used together or sequentially. Each method having its favorite target.

The water thus produced responds to a treatment process totally controlled by the SFEC, which relies in particular on the following technologies :

Ultra-pure water is the utility most widely used in laboratories, sterilization units and the pharmaceutical industry, notably for the preparation of the vast majority of medicines.

Ultra pure water is the most used utility in laboratories, sterilization units and the pharmaceutical industry especially for the preparation of the vast majority of drugs.

Moreover, in the hospitals or the care units, the water of the city network requires a physicochemical, bacteriological and endotoxic treatment before being able to be used safely within the framework of the dialysis. Therefore, this treated water strictly complies with the quality standards defined by the Pharmacopée French and European.

The physicochemical, bacteriological and endotoxic treatment of water for medical use controlled by SFEC is an essential process to guarantee water of excellent medical quality and to prevent all risks, immediate or long term..

The design of SFEC treatment systems for medical use has been designed and studied to enable :

Our strong points :

The water treatment systems for medical use that we build are based on an absolute safety philosophy based on a concept of redundancy.

Indeed, each element is bypassable either manually or in automatic mode. Whatever the malfunction detected by the PLC, the user is immediately informed and the alarm report can be sent back to our service technician…

If an osmosis unit should have a major problem (malfunction of the booster pump), it would be sufficient to acknowledge the alarm and turn a key to automatically actuate a bypass composed of electric valves.

Each part of the process chain is equipped with various sensors whose measured values are all sent back to the PLC. All these measures can be included in a traceability protocol à la carte, which means that it is the user who chooses according to his own criteria the values he wishes to export within a tracing system…

The entire installation is managed by a programmable controller that ensures fully automatic operation of the installation. The different parameters are entered using a user-friendly touch screen. The variety of control variants ensures maximum flexibility and operational safety. All important operating parameters are recorded electronically. Remote monitoring is part of our services. The majority of our installations are equipped with this device that allows us from our headquarters or from any phone jack to connect to your installation, to consult the various operating parameters.

The degree of safety is such that only a break in the supply of water or electricity could completely immobilize the water treatment plant. Indeed, all vital organs are doubled and have forced marches. Even if the automaton of the installation had to have a malfunction, you have a forced march which allows you to finish with peace of mind the current dialysis session.

SFEC processing chains combine several filtration methods that are used together or sequentially. Each method having its favorite target.

The ultra-pure water thus produced responds to a treatment process totally mastered by the SFEC and which comprises several stages :

For heat disinfection, we offer loop ultrafiltration associated with heat disinfection (85°C). These coupled techniques are effective on bacteria and endotoxins. They guarantee water of exceptional quality.

Almost all sectors of activity that use water in their process have the possibility of reprocessing it to reuse it in various forms.

Faced with the major challenges of climate change, which results in repeated episodes of drought, combined with the evolution of our water uses and demographic growth, requires the emergence of new solutions and strongly encourages us to review our water management models to guarantee sustainable access to water for all in a reasonable manner.

This is why the recycling and recovery of water which has already been used for another use after treatment (industrial process water for example) can constitute an excellent alternative to respond sustainably to these new challenges because it contributes to increasing the availability of water on a territorial scale or even in the world.

Tertiary or industrial sectors of activity (textiles, automobiles, refineries, nuclear power plants, cement plants, etc.) consume enormous volumes of water.

On an industrial site, water is everywhere. It is used intensively as: processing water, cooling water or cleaning water or even all three at the same time…

Many industries have a conservative approach and are often concerned about the lack of tangible results and the need for a tailor-made solution.

SFEC is able to propose and implement alternative techniques and new tailor-made solutions which make it possible to recycle altered and slightly soiled water for various other uses not intended for human consumption and which do not present a risk to health. This reuse of water can be internal (within the same structure) or external (use by another structure).

The reuse of this water constitutes a circular economy approach, beneficial from an environmental, societal and economic point of view.

OUR SERVICES

In order to guarantee the success of your projects, the SFEC company and its teams of engineers and technicians specialized in water treatment are at your disposal to study the best solutions.

Purchasing department

Secretariat

Secretariat

Maintenance department

Design office

Construction department

TESTIMONIALS

"Very nice installation and high quality equipment. This containerized drinking water production station delights the occupants of the base life."

Petrofac Company Aide humanitaire"Reverse osmosis installation with a very good price/water quality ratio. The SFEC team was proactive in moving the project forward despite the internal constraints specific to our group."

Groupe Arkema Préparation homéopathiques"Very professional-experts: They know what they are talking about - Knowledge of deadlines and maintaining commitments - Very good human contact."

Société Cosmépharm Restauration collective"Very beautiful ultrafiltration station installation and high quality equipment. This water purification station fully meets the requirements set by the regulations. Thank you to SFEC for honoring its commitments !"

Collectivité publique Restauration collective"The SFEC water treatment installation fully meets the expectations of our intensive care unit. We are very satisfied with the work accomplished and the ultrapure water quality !"

Centre Hospitalier Universitaire Restauration collective

Subscribe to our newsletter to get updated information, news, information or promotions.

"The operational team is satisfied with the quality, performance and options integrated into the latest ultrafiltration station delivered and installed this year 2023."

Les Eaux Minérales d’Oulmès Services collectifs